SHC M2 TYPE ANNULAR CUTTER HIGH SPEED STEEL

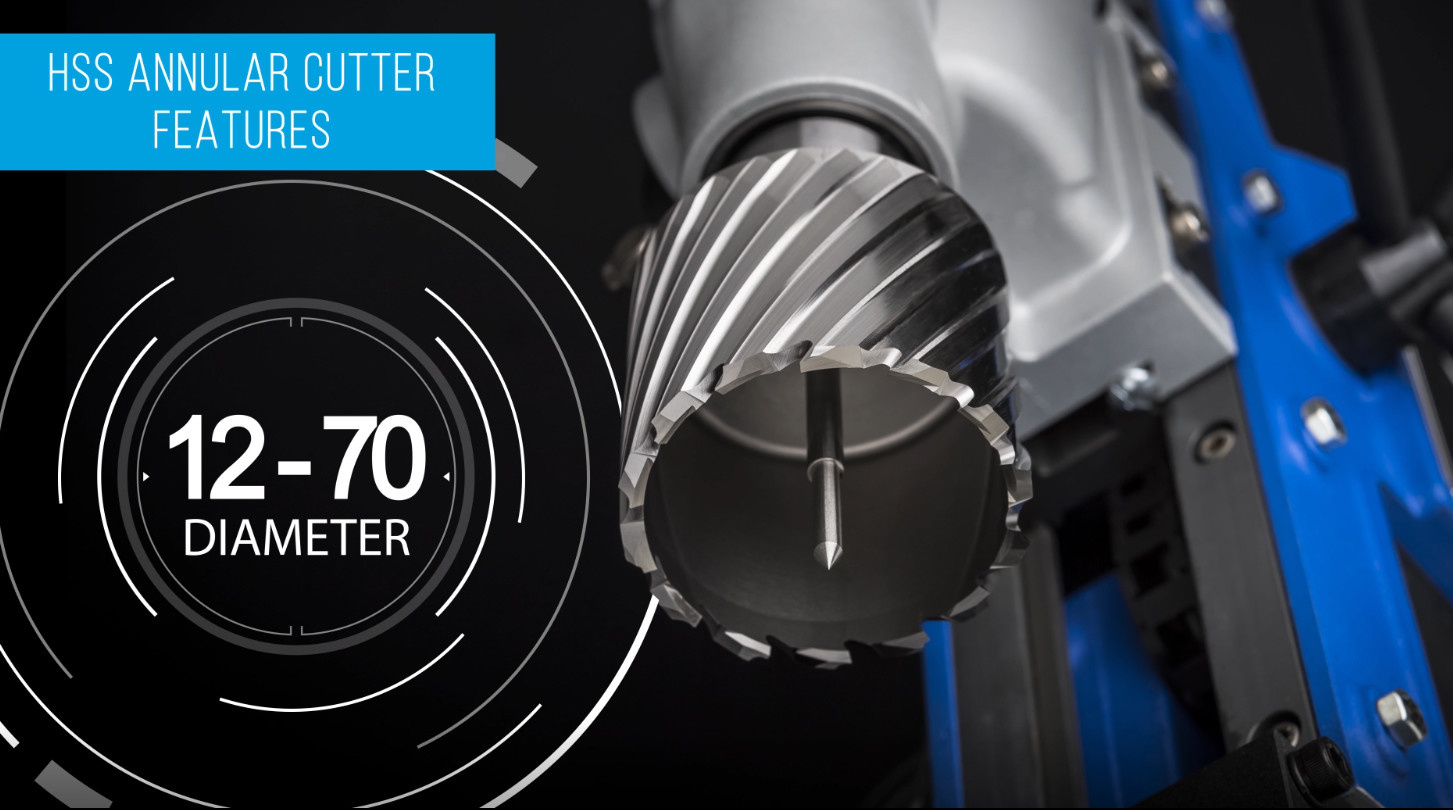

3keego annular cutter SHC type is made of M2 High-speed steel material. SHC M2 Standard Type is fully ground with high heat resistance. High precision drilling and produces a smooth surface.

Category: SHC M2 StandardFeatures

High

Speed Steel Annular cutter (HSS)

The days of grabbing a magnetic drill and

plowing a twist drill through the steel, blue chips flying, are gone. Annular

cutters are the standard for hole making with magnetic drills. These cutters

make the job easier, more efficient and save shops money.

High-speed steel (HSS) annular cutters

3keego HSS Annular Cutters are designed to

drill holes on mild to hard steels. HSS Annular Cutters are made from M2 and

M42 HSS material. Comes with Titanium Coated for a longer life span.

An HSS annular cutter is a hollow tool that provides multiple cutting edges. Annular cutters drill a burr-free hole by cutting material around the periphery of the hole and ejecting the center as a solid usable slug. It’s an efficient way to create holes ½” to 4” diameter and up to 3” deep. Final holes are smooth and no reaming, predrilling or step drilling is required. The wall thickness of the cutter is only ¼” thick so that no matter what size hole you are cutting, you are only removing a small amount of material around the edge of the hole.

Annular

cutters are manufactured in several different configurations including carbide-tipped

annular cutters and carbide

tipped stacked annular for

maximum cutting performance.

Another

factor in the HSS annular cutter equation is tooth geometry. Cutting multiple

plates at once does not use the same tooth angles as when cutting a single

sheet. There are different geometries and features companies put on annular

cutters to help ensure the most success.

And

don’t forget coatings. Manufacturers can apply a variety of different coatings

to increase the tool life in harder materials. Remember, you get what you pay

for. Also, look for annular cutters that can be re-sharpened. That will save

you even more money in the long run.

Other

important factors

After

you choose the proper annular cutter, there are other factors to help lead you

to greater success.

1. Always use

coolant and use the machine's thru-the-spindle coolant whenever possible.

Cutting tools love coolant.

2. Use good steady

feed pressure. Make sure you are pulling a good chip.

3. Aim to get

close to the recommended RPM for the cutter and material. Your tool life will

thank you.

4. Use a sharp

annular cutter, because sharp edges just cut better.

5. Ensure the

arbor and mounting system holding the tool is rigid and secure otherwise you

can quickly dull or break a cutter.

6.Always use the pilot

pin. Slugs must be ejected.

What are

Annular Cutter Used For?

Material

Cast Iron

Carbon Steel

Metal Sheets

Structural Steel

Application

General Construction

Pipes and Tubes

Bridge Building (I-beam)

Benefits and Advantages of HSS Annular Cutter

Fast (Time Saving)

Since

an annular cutter removes only the material at the periphery of the hole, it is

3 to 4 times faster than twist drill bit. Besides, an annular cutter with pilot

pin can finish a hole by one operation without pre-drilling for a pilot hole.

Efficient (Energy Saving)

Due to

the annulus shape and thin wall design (4mm for each diameter), the annular

cutter does not have to drill the complete material of the hole which lowers

the energy, effort and thrust compared to conventional drill bits.

Less wear (Longer life)

While

the cutting surface is distributed to multiple cutting edges, the contact

between annular cutter and the material becomes much less. Also, no matter how

big the hole you are going to drill, the thin wall (4mm) of the annular cutter

will cut only at the periphery of the hole. Therefore, an annular cutter with a

good design has a longer service life with best performance.

Clean Hole (Burr-free)

With

specially designed cutting teeth geometry compared to conventional drill bits,

an annular cutter can create a burr-free hole in metal. Besides, since there is

only a few chips made, the cleaning work after drilling is very easy and fast.

Specifications

| SHC M2 Standard Type | ||||||||

|

|

|

| |||||

| Type | SHC 30 |

SHC 55 |

SHC 75 |

SHC 110 | ||||

| Annular cutter |

M2 High Speed Steel (HSS) | M2 High Speed Steel (HSS) |

M2 High Speed Steel (HSS) |

M2 High Speed Steel (HSS) | ||||

| Cutting depth (mm) | 30 mm | 55 mm | 75 mm | 110 mm | ||||

| Nominal diameter | ||||||||

Metric (mm) | Ø12 ~ Ø35 mm | Ø12 ~ Ø50 mm | Ø18 ~ Ø50 mm | Ø19 ~ Ø50 mm | ||||

Imperial ( " ) | Ø1/2" ~ Ø1-3/8" | Ø1/2" ~ Ø1-3/8" | Ø3/4" ~ Ø2" | Ø3/4" ~ Ø2" | ||||

| Ejector pin | ||||||||

Ø13 mm below | Ø4.75 x 3.6 x 75L | Ø4.75 x 3.6 x 100L | - | - | ||||

Ø14 mm above | Ø6.35 x 4.8 x 75L | Ø6.35 x 4.8 x 100L | Ø6.35 x 125L | Ø6.35 x 170L | ||||

| Shank type | ||||||||

Weldon(Ø19.05mm) | √ | √ | √ | √ | ||||

Onetouch(Ø19.05mm) | √ | √ | - | - | ||||

| Coating |

Standard |

Standard |

Standard |

Standard | ||||

| 6 Piece set | √ | √ | - | - | ||||

| Applications | ||||||||

| Steel | √ |

√ |

√ |

√ | ||||

| Stainless steel | - | - | - | - | ||||

| Cast iron | √ |

√ |

√ |

√ | ||||

| Aluminum | √ |

√ |

√ |

√ | ||||

| Stacked steel |

- |

- |

- |

- | ||||

| Railway | - |

- |

- |

- | ||||

| Hardox |

- |

- |

- |

- | ||||

| Machine | ||||||||

| Portable drilling machine | - | - | - |

- | ||||

| Pillar drilling machine | - | - | - |

- | ||||

| Magnetic drilling machine | √ |

√ |

√ |

√ |

||||

| Suitable Adapter | ||||||||

| Fein to Weldon | √ |

√ |

√ |

√ |

||||

| One Touch to Weldon | √ |

√ |

√ |

√ |

||||

| Adapter pin |

||||||||

Ø13 below |

Ø4.75 x 3.6 x 100L |

- |

- |

- | ||||

Ø16 above |

Ø6.35 x 4.8 x 100L |

Ø6.35 x 125L |

Ø6.35 x 170L |

- |

||||

| Suitable Extensions | ||||||||

| 50L | √ |

√ |

√ |

√ |

||||

| 75L |

√ |

√ |

√ |

√ |

||||

| 100L |

√ |

√ |

√ |

√ |

||||

| 150L |

√ |

√ |

√ |

√ |

||||

| 200L |

√ |

√ |

√ |

√ |

||||

| 250L |

√ |

√ |

√ |

√ |

||||